- Description

- Brochure

- Applications

- Performance Curves

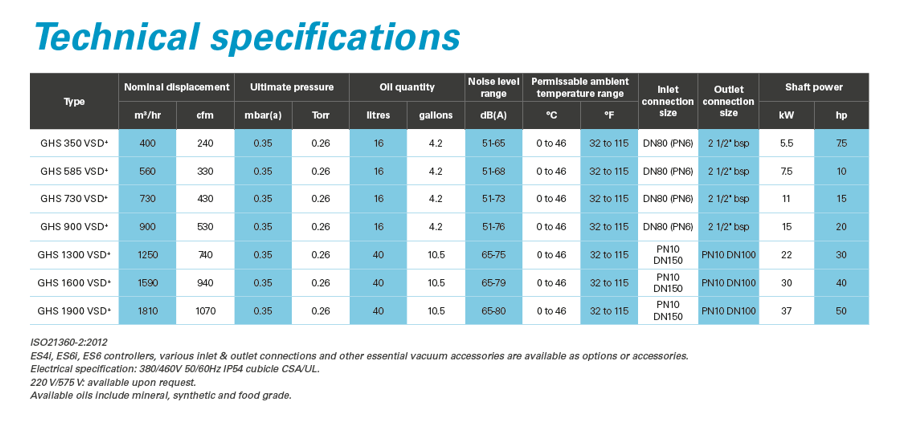

- Technical Specifications

These unique products offer

- Superior performance against benchmarked oil-sealed and dry vane vacuum pump technologies.

- Quiet operation – Noise level is far below that of comparable technologies.

- Reduced environmental impact due to ultra-high oil retention at all operating pressures.

- Increased efficiency – State-of-the-art screw technology, Variable Speed Drive (VSD) and innovative motor design combine to produce a leap forward in efficiency.

- Sustainable productivity thanks to built-in efficiency.

Outstanding, unmatched benefits

These vacuum pumps consume approximately 50% less energy than alternative technologies. They are among the most energy-efficient oil-lubricated vacuum pumps on the market in the capacity range where some other technologies (e.g. oil-sealed vane) start to become mechanically inefficient and expensive in terms of capital expenditure.

As much as 90% of the electrical energy used by a vacuum solution is converted into heat.

With Atlas Copco’s integrated energy recovery system, it is feasible to recover up to 75% of that power input as hot water without any influence on the machine’s performance. Through efficient usage of the recovered energy, you obtain important energy cost savings and a high return on investment

Long-lasting components

The oil separator is designed for highly efficient oil coalescing with ultra-low back pressure, which means less energy consumption. This contributes to a long oil separator life that is double that of a comparable oil-sealed vane vacuum pump. Another contribution to oil separator life is the patented design which never allows the filtration media to be overloaded, so they last much longer. This is great news for your maintenance budget.

Energy savings

VSD and set-point control – not normally features of vacuum pumps – lead to significant energy savings. Set-point control allows you to optimize the energy you use to maintain your process vacuum level and thereby optimize your process efficiency and performance. The lowest possible flow will be delivered to match your required vacuum level or speed – nothing is wasted!

Optimal flexibility

A unique water handling capability provides you with the versatility and flexibility you need.

VSD for 50% average energy savings

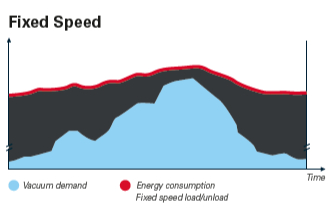

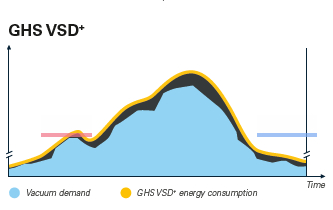

In almost every production environment, the need for vacuum fluctuates depending on different factors such as process changes, the time of day, week or even month. Extensive measurements and studies of demand profiles show that there are many substantial variants with regards to vacuum demand.

Why Atlas Copco variable speed drive technology?

- On average 50% energy savings with an extensive flow range (10-100%).

- Reduced electrical installation costs (fuse and cable size).

- Integrated Elektronikon Graphic controller controls the motor speed and high efficiency frequency inverter.

- Eliminates peak current penalty during start-up experienced with stop-start machines.

- EMC compliance to directives (2004/108/EG)

Product Brochure

GHS VSD+

Innovative, intelligent vacuum pumps

HOT SPOT APPLICATIONS

The GHS VSD+ Series is suitable for a range of applications in various industries. The capacity range of these pumps means they are ideal for central systems or larger installations. Here are some of the key ones

Holding, lifting and moving applications

- Pick and place – especially electronics.

- Envelope manufacture.

- General packaging.

- Woodworking.

Preserving applications

- Meat packaging (flat, vacuum packs, controlle atmosphere packaging).

- Poultry packaging.

- Modified atmosphere packaging (gas flushing).

- Canning.

When a clean environment is essential

- Heat treatment, nitriding and metallurgy.

- Altitude simulation.

- Drying and general evacuation duties.

- Coating.

- And many more…

Forming and shaping applications

- Plastics (e.g. bathtubs, shower trays, white goods internals).

- Packaging materials (e.g. thermoformed parts).

Humid applications

- Roof tile and brick manufacture.

- Pipeline drying.

- Salad cooling.

Standard

This machine focuses on delivering the exact performance you demand, at the lowest possible lifecycle cost. Ideal for applications where you need to maintain a set vacuum level (set point).

Turbo

This fast evacuation version enables faster cycle times – meaning more production. It’s ideal for meat, cheese and chicken packaging, as well as cooling, freeze drying and general vessel evacuation applications.

Turbo versions for fast cycling machines are available in 350, 585, 730, 1300 and 1600 sizes and come with upgraded motors and logic.

Humid

Suitable for high water content duties (up to 100%), for applications such as plastics, clay molding,drying pipelines, salad cooling, freeze drying etc.

Performance Curve GHS VSD+ Vs Fixed Speed

Elektronikon® monitoring system

Elektronikon® is a state-of-the-art monitoring system for your vacuum pumps. It is simple and comprehensive, and leads to energy savings. It can also integrate your plant management system thanks to a remote monitoring option.

Easy to use

- 3.5-inch high-definition color display with clear pictograms, 32 language settings.

- Additional LED indicator for service.

- Graphical display of key parameters (day, week, month).

- Fully automated pump with limited manual handling.

Plant management system

- The machines can be controlled by a multiple pump controller ESv – integrated or external. Remote monitoring and control can also be installed with a Gateway (Modbus or Profibus).

Comprehensive

You get all the information for the everyday management

of your vacuum pump, as well as the alarms, safety shutdowns

and maintenance:

- Monitoring: Vacuum pump operating status, recording of running/ stopped hours, programmable timers, temperature/pressure read-outs, set point control and other settings.

- Safety: Warning indications, fault and shutdown indications.

- Service: Service operations, remote control (optional).

SMART LINK

SMART LINK: more than just a watchful eye

SMARTLINK is a flexible solution for data monitoring: easy to install and customize and user-friendly. Central vacuum systems and individual machines are connected to your engineering team by Atlas Copco. SMARTLINK brings system relevant data to your mobile phone, smartphone and PC. Whenever you have access to the Internet, it is possible to display the information you need; from machine alarms and faults to visualized representations of demand and load for your complete site vacuum installations.

This allows you to respond quickly to changing circumstances. Service calls can be efficiently planned and production losses minimized. SMARTLINK is flexible and delivers as much or as little info as you choose.

Features (Internet connection required)

- Web portal: event overview of the last 30 days, access to service data and monthly status report by email.

- Logging + download service data for the last 30 days (Excel, Word, PDF).

- Requirement of machine-related services (service, spare parts) directly via web portal.

- SMS/email notification (service, failures and warnings).

- Online trend graph: status display.

| Rated AC Power Output | 7,600 VA |

|---|---|

| Maximum AC Power Output | 8,350 VA |

| AC Output Voltage | 240 VAC (211-264) |

| AC Frequency | 60 Hz (59.3-60.5) |

Reviews

There are no reviews yet.